Safety & Cleanliness

Setting our goal as “zero workplace accidents,”

we strive to create a safe work environment for everyone.

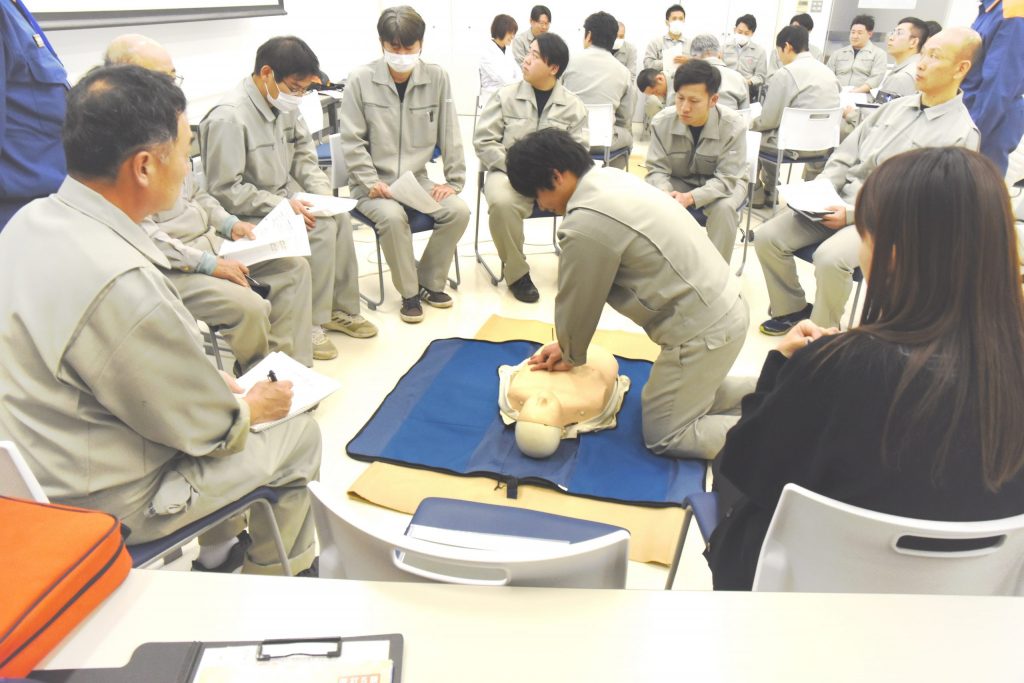

Health and safety of our employees always come first

We continue to train our staff to have a good understanding of facility and procedure-related safety protocols

Management of Occupational Safety and Hygiene

We hold “Safety and Hygiene Committee” monthly, focusing on eliminating the pre-existent risks through risk assessments. Mental health and other health-related concerns of our workers are also important to us.

Through several projects in effect, such as 5S activity, safety protocols, thorough risk assessment, education and support, PDCA cycle, etc., we make sure that our work environment is ideal to all.

Occupational Safety & Hygiene Act

■Occupational Safety Courses

■First-aid classes taught by instructors, etc.

■Instructions on risk assessment

■Step-by-step instructions on factory procedures

■Instructions on machine operation risk management

■Lectures on special techniques

■Attendance of other lectures outside of the company

Self-improvement of safety & hygiene management

■Setting of safety & hygiene standard

■Safety & Hygiene Committee meetings

■Participation of national safety week and national occupational health week, and establishment of company-wide safety week post long-term holidays

■Facility inspection by the Safety & Hygiene Committee and reinforcement of safety rules to the employees

■Forklift self-inspection

■Enforcement of PPE

■Knowledge check of procedure steps

Promotion of good health and comfortable work environment

■Stress checks

■Enforcement of no-overtime days

■Work-hour managements & assessments, and support for health care

■Access to occupational physician and health consultation

■5S activity

■Proactive prevention and immediate treatment of heat strokes and related illnesses

Promotion of Certificate Acquirement

■Certificates for handling hazardous materials

■Lessons for forklift license